What is Magnetic Drill?

- Magnetic Drill is a Portable drilling machine with an electromagnetic base or a permanent magnet base. It can drill hole using Annular Cutters in various materials thereby producing accurate, burr free holes

Why to use Magnetic Drill?

- Owing to its portability it can easily be carried to the work piece, instead of bringing the work piece for Drilling

| model | Specification |

|---|---|

| Moter rated power | 1100 W |

| No load speed | 700 rpm |

| Rotating direction | Clockwise |

| Arbor bore | 19.05mm (3/4") dia. |

| Colling method | Internal colling |

| Voltage | AC 220V~240V |

| Frequency range | 50-60Hz |

| Magnet deadlift | 10000 N |

| Max.cutting dia. (annular cutter) | 35mm (1-3/8") |

| Max cutting depth | 50mm (2") |

| Stroke | 120mm |

| Magnet footprint | 165mm × 80mm × 43mm |

| Weight | 10.5kg |

Working Videos

Problem Solving

Easy to use

Reduce tapping time

More Accurate tapping

Zero Tap Breakage

Benifites

They are often compact and lightweight, making them easy to transport to different job sites.

The magnetic base ensures a secure attachment to metal surfaces, providing stability during drilling.

They can be used in various positions, including vertical, horizontal, and overhead, making them suitable for different drilling applications.

Magnetic drill machines typically have high drilling speeds and can handle large diameter holes efficiently.

The magnetic base prevents the drill from slipping or moving during operation, reducing the risk of accidents.

Tapping Machine

| Basic Configuration | SMT12 | SMT16 | SMT24 | SMT36 |

|---|---|---|---|---|

| TAPPING CAPACITY | M3-M12 | M3-M16 | M6-M24 | M6-M36 |

| WORKING AREA | 1100MM | 1100MM | 1200MM | 1200MM |

| SUPPLY VOLTAGE POWER | 600W/220V | 1200W/220V | 1200W/220V | 1200W/220V |

| SPINDLE RPM | 0-618 | 0-312 | 0-200 | 0-156 |

Working Videos

Problem Solving

Easy to use

Reduce tapping time

More Accurate tapping

Zero Tap Breakage

Benifites

They Can create thereads quickly and accurately, reducing production time compared to manual tapping methods.

Tapping machines produce threads with consistent quality, ensuring uniformity in the final product.

These machines are capable of tapping holes with precise thread depths and pitch, leading to better fit and function of assambled components.

By automating the tapping process, these machines reduce theneed for manual labor, saving time and reducing the risk of errors.

Tapping Drilling Machine

Cantilever type drilling and tapping machine, with a radius of 850 mm, a diameter of 1.7 meters, and a 360- degree rotation. It is efficient and accurate for drilling where it is pointed. It is fast and flexible to switch and tapping. It can complete drilling and tapping without moving the workpiece Angle and other processes, saving labor, double the efficiency. The fuselage is made of steel structure, which is stronger and more durable.

| model | Specification |

|---|---|

| Drill ability | 3-16MM |

| Tapping ability | M5-M20 |

| Working radius | 85cm |

| Height | 40cm |

| Servo motor (220V) | 1200W |

| Drill depth | 80mm |

| Weight for machine | 140 KGS |

| Weight for Working table | 120Kgs The working table is optional |

Working Videos

Problem Solving

Easy to use

Reduce tapping time

More Accurate tapping

Zero Tap Breakage

Benifites

It can perform both tapping and drilling operations, allowing for a wider range of machining capabilities in a single machine.

By integrating tapping and drilling functions, the machine reduces the need for multiple setups and tool changes, streamlining the machining process and improving efficiency.

Electric tapping drilling machines are equipped with motors and controls that enable precise positiing and operation, ensuring accurate hole machines are equipped with motors and controls that enable precise positioning and operation, ensuring accurate hole placement, thread depth, and tapping speed.

With electric motors powering the tapping and drilling actions, these machines are often easier to operate than manual alternatives, reducing the skill level required for operation and minimizing the risk of errors.

Electric tapping drilling machines can increase productivity by allowing for faster cycle times, reduced setup times, and improved overall machining efficiency.

Drill Grinding Machine

- Quick re-sharpening of HSS or Carbide drills of taper or straight shank.

- Two separate stations for point angle grinding and relieving

- Very easy to learn operation by instruction sheet.

- CBN grinding wheel for HSS drills and all size collets included as standard equipment. SDC grinding wheel for carbide drill and additional collets are optional.

| model | drill dia capacity |

dia capacity with optional collets |

point angle adjustment |

Power | N.W.KGS. |

|---|---|---|---|---|---|

| SDG - 13 | 3 - 13 | 3 - 13 | 90℃ - 135℃ | AC-220V / 120W | 10 |

| SDG - 20 | 3 - 20 | 3 - 20 | 90℃ - 135℃ | AC-220V / 120W | 11 |

| SDG - 26 | 13 - 26 | 8 - 30 | 85℃ - 140℃ | AC-220V / 250W | 29 |

Working Videos

Problem Solving

Easy to use

Reduce tapping time

More Accurate tapping

Zero Tap Breakage

Benifites

By regrinding dull or worn-out drill bits instead of replacing them, companies can save money on purchasing new tools.

Regrinding restores the sharpness and cutting edges of drill bits, allowing them to be used for longer periods before needing replacement.

Sharp drill bits cut more efficiently, reducing the time required to complete drilling operations and improving overall productivity.

Regrinding ensures that drill bits maintain precise dimensions and cutting geometry, resulting in better quality holes finished

End Mill Grinding Machine

- Quick re-sharpening of HSS or Carbide end mills.

- Very easy to learn operation by instruction sheet.

- SDC grinding wheel for carbide drills and all sizes collets included as standard equipment. CBN grinding wheel for HSS drill and additional collets are optional.

- Grinds 2-Flute, 3-Flute, 4-Flute end mills and bigger than 12 dia 6-Flute end mills.

| model | End Mill Dia Capacity |

Point Angle | Power | N. W. KGS. |

|---|---|---|---|---|

| SEM - 14 | 4 - 14 | 0° - 5° | AC-220V / 180W | 12 |

| SEM - 30 | 13 - 30 | 0° - 5° | AC-220V / 250W | 25 |

Working Videos

Problem Solving

Easy to use

Reduce tapping time

More Accurate tapping

Zero Tap Breakage

Benifites

These machines can grind end mills with high precision, ensuring accurate dimensions, cutting geometry, and edge sharpness.

Instead of replacing dull or worn-out end mills, companies can regrind them using the machine, saving on tool replacement costs.

Regrinding end mills restores their cutting performance, allowing them to be used for longer periods before needing replacement.

Endmill grinding machines often offer the ability to customize cutting geometries and angles to suit specific machining requirements, enhancing versatility.

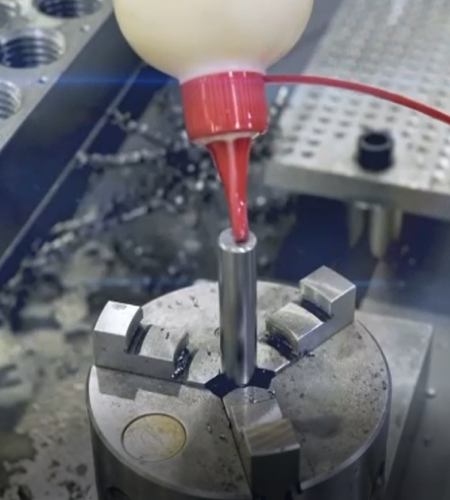

Small EDM Drill Machine

- Small EDM drill machines are compact and versatile tools used for precision drilling in various materials, especially metals. They use electrical discharge to erode the material, making them suitable for intricate and precise drilling tasks. These machines are commonly used in industries such as manufacturing, aerospace, and toolmaking for creating holes with high precision and accuracy. If you're interested in purchasing or learning more about small EDM drill machines, you can explore options from manufacturers or suppliers specializing in machining equipment.

Features

- It can quickly remove taps, drill bits, screws, reamers, plug gauges and other

| model | AMQD-600B | AMQD-800B | AMQD-1000B |

|---|---|---|---|

| Input | AC220V 50/60HZ | AC220V 50/60HZ | AC220V 50/60HZ |

| Power | 600W | 800W | 1000W |

| Voltage | 80V | 80V | 80V |

| Electrode Range | 0.5mm - 10mm | 0.5mm - 10mm | 0.5mm - 10mm |

| Manual Travel | 310mm | 310mm | 310mm |

| Automatic Travel | 60mm | 60mm | 60mm |

| Processing Speed | ≥ 1mm/min | ~1.5mm/min | ≥ 2.0mm/min |

| Size | 380 ✕ 200 ✕ 320mm | 380 ✕ 200 ✕ 320mm | 380 ✕ 200 ✕ 320mm |

| Weight | 15KG | 17KG | 17KG |

Working Videos

Problem Solving

Easy to use

Reduce tapping time

More Accurate tapping

Zero Tap Breakage

Benifites

These machines can grind end mills with high precision, ensuring accurate dimensions, cutting geometry, and edge sharpness.

Instead of replacing dull or worn-out end mills, companies can regrind them using the machine, saving on tool replacement costs.

Regrinding end mills restores their cutting performance, allowing them to be used for longer periods before needing replacement.

Endmill grinding machines often offer the ability to customize cutting geometries and angles to suit specific machining requirements, enhancing versatility.